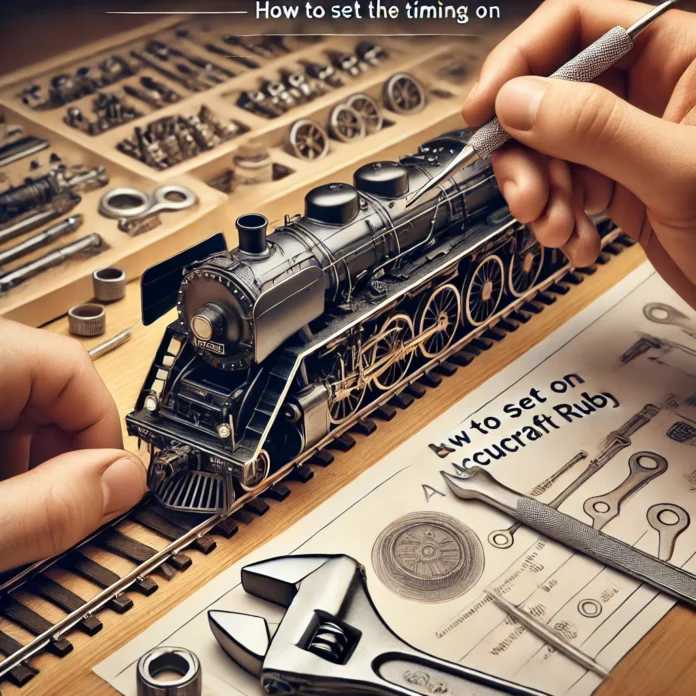

Accucraft Ruby live steam engine is prized by beginner for their simplicity and performance. But, setting the correct timing on an Accucraft Ruby can be a careful process that needs attention to every point. Proper timing confirms smooth operation and boosted performance, making it an important skill for any live steam lover.

In this guide, we will tell you about the process of setting the timing on an Accucraft Ruby. In case, you’re new to live steam or an experienced modeler, this full tutorial will help you set your Ruby for excellent performance.

What is Timing on an Accucraft Ruby?

Timing on an Accucraft Ruby mentions to the setting of the engine’s valve gear to confirms the proper opening and closing of steam ports at the right moments. This directly affects the engine’s performance, speed, and smoothness of operation.

Without proper timing, your Ruby may experience:

- Low performance.

- Irregular running or blockage.

- Excessive steam consumption.

By setting the timing correctly, you can get a perfectly organized operation that increases both performance and reliability.

Tools Needed for Setting Timing

Before you begin, collect the following tools and supplies:

- Small screwdrivers (flathead and Phillips).

- A pair of small wrenches (typically included with the model).

- A ruler or calipers for accurate measurements.

- A flashlight or small lamp for better visibility.

- The Ruby’s instruction manual (if available).

Holding the right tools on hand will make the process smoother and lower the risk of damaging gentle components.

Step-by-Step Guide to Setting the Timing

Follow these steps to set the timing on your Accucraft Ruby accurately:

1. Disassemble the Locomotive

Start by carefully removing the body shell of the Ruby to show the valve gear and cylinders. Confirms that all components are clean and free from waste. This step gives you clear reach to the timing tool.

- Use the screwdrivers to remove screws holding the body shell.

- Keep screws and small parts organized so that you won’t lose them.

2. Identify the Valve Gear Components

Familiarize yourself with the important parts of the valve gear, including:

- Eccentric Crank: Controls the movement of the valve.

- Valve Rod: Connects the nutty lever to the steam valve.

- Steam Valve: Opens and closes for the entrance of steam into the cylinders.

Understanding these points will help you make accurate adjustments.

3. Rotate the Wheels to Find Top Dead Center (TDC)

Top Dead Center (TDC) is the point where the device reaches its maximum reach within the cylinder. To find TDC:

- Slowly rotate the driving wheels while observing the pistons.

- Stop when the piston in one cylinder is fully open.

Mark this position as a connection for adjusting the valve gear.

4. Adjust the Eccentric Crank

The nutty lever controls the timing of the steam valve. To adjust it:

- Loosen the holder screw on the nutty lever.

- Rotate the lever slightly forward or backward to manage with TDC.

- Tighten the screw to secure the crank in place.

Repeat this process for the other side of the locomotive.

5. Fine-Tune the Valve Rods

Next, adjust the valve rods to confirm the steam ports open and close at the correct moments:

- Rotate the driving wheels slowly and observe the valve motion.

- Use a wrench to adjust the length of the valve rods as needed.

- Confirms that the valve opens just before the device begins its power stroke.

6. Test the Timing

Fix up the Ruby and conduct a test run:

- Place the engine on a rolling road or test track.

- Apply steam pressure and observe its function.

- Listen for smooth and continuous sounds from the cylinders.

If you notice irregularities, revisit the adjustments and adjust as needed.

Tips for Accurate Timing

Getting perfect timing may need several trials. Keep these tips in mind:

- Work Slowly and Carefully: Accuracy is hard when adjusting small components.

- Use Reference Marks: Marking positions on the lever and valve rods can help track adjustments.

- Seek Expert Advice: If you’re new to live steam, don’t delay to ask experienced beginner or online forums.

- Keep a Record: File your adjustments to track what works best for your Ruby.

- Practice Patience: Timing adjustments can be complex and may need multiple attempts.

Conclusion

Setting the timing on an Accucraft Ruby is a satisfying process that increases your engine’s performance and reliability. By following the steps mentioned in this guide, you can set your Ruby to run smoothly and skillfully. With patience and practice, you’ll get confidence in maintaining and boosting your live steam engine.

If you’re a learner or an experienced modeler, mastering this skill add in the joy of operating your Ruby. Take your time, enjoy the process, and watch your engine perform at its best.

Frequently Asked Questions (FAQs)

1. How often should I check the timing on my Accucraft Ruby?

It’s a good practice to check the timing regularly, especially if you notice uneven running or after long term use.

2. Can I set the timing without disassembling the Ruby?

After minor adjustments may be possible without complete disconnection, reaching the valve gear for accurate timing usually needs removing the body shell.

3. What are the signs of incorrect timing?

Symptoms of incorrect timing include uneven running, blockage, extra steam use, or a lack of power.

4. Is it possible to damage the locomotive while setting the timing?

Yes, forcing components or over-tightening screws can cause damage. Always handle parts with soft hands and use the correct tools.

5. Can I seek professional help for setting the timing?

Absolutely. If you’re not sure about the process, ask a professional or an experienced starter to avoid mistakes.

6. Are there resources available to help with timing adjustments?

Yes, online forums, video tutorials, and Accucraft’s official files are excellent ways for additional guidance.